Foam Sheet Cuttings

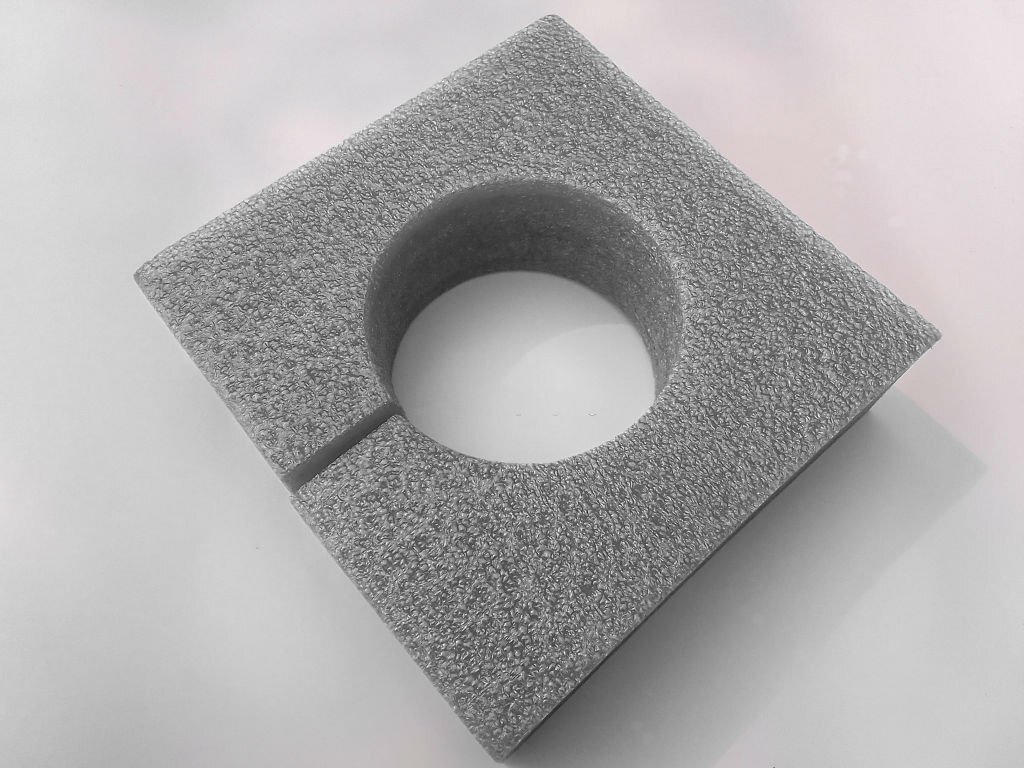

EP foam sheet cutting packaging is a popular method of protecting and securing products during transportation. This type of packaging involves the use of EP (expanded polyethylene) foam sheets that are cut into specific sizes and shapes to provide a custom fit for the product being shipped.

Description

EP foam sheet cutting packaging is a popular method of protecting and securing products during transportation. This type of packaging involves the use of EP (expanded polyethylene) foam sheets that are cut into specific sizes and shapes to provide a custom fit for the product being shipped. EP foam is a lightweight material that is durable and offers excellent shock absorption properties. It can be easily cut into various shapes using a cutting tool, such as a knife or saw.

Once cut, the foam pieces are placed around the product and secured in place using tape or adhesive. EP foam sheet cutting packaging is ideal for protecting a wide range of products, including electronics, glassware, and fragile items. Its lightweight nature also makes it an ideal choice for reducing shipping costs. To ensure the proper fit and protection of your product, it is best to work with a packaging professional who can design custom EP foam sheet cutting packaging to meet your specific needs.

We use high grade raw material and cutting-edge technology, these sheets are highly accepted by our customers. Further, our sheets are thoroughly tested against various quality parameters before final delivery at client’s end. Clients can avail our sheets as per the specific requirements at industry competent prices.

Features Of E.P.E. Foam Sheet:

EP foam sheets, which stand for Expanded Polystyrene foam, are a popular type of packaging foam due to their lightweight and shock-absorbing properties.

Here are some of the features of EP foam sheets packaging:

- Lightweight – EP foam sheets are extremely lightweight, making them an ideal material for packaging fragile and delicate items like electronics, glassware, and artwork.

- Shock-absorbing – EP foam sheets have excellent shock absorption properties, which helps to protect the enclosed items from impacts, vibration, and other transit-related damages.

- Insulating – EP foam sheets provide insulation to the packaged items, protecting them from extreme temperature fluctuations during transit.

- Durable – EP foam sheets are long-lasting and resistant to water, moisture, and chemicals, making them a great choice for long-term storage and transportation.

- Recyclable – EP foam sheets are easily recyclable, which makes them an eco-friendly alternative to traditional packaging materials like bubble wrap and Styrofoam. Overall, EP foam sheet packaging is an excellent choice for industries that require reliable and affordable packaging solutions that ensure the safety of their products during transit.

Used In Industries Like:

- Packing

- Automobiles

- Construction

- Sports

- Insulation

Features & Advantages Of E.P.E. Sheet!

Expanded polystyrene (EPS) foam sheets are versatile materials that are widely used in packaging applications due to their lightweight, durable, and insulating properties.

Here are some of the main packaging applications of EPS foam sheets:

- Protective packaging: EPS foam sheets are commonly used as protective packaging material for fragile items such as electronic devices, glassware, and ceramics. The foam sheets can be cut into various shapes and sizes to fit the items and provide cushioning during transportation.

- Food packaging: EPS foam sheets are popularly used in food packaging applications due to their thermal insulation properties. The foam sheets help keep food hot or cold for longer periods of time, making them ideal for transporting items like seafood, meat, and perishable goods. EPS foam food packaging products include trays, cups, and containers.

- Electronics packaging: EPS foam sheets are commonly used in electronic packaging applications due to their anti-static properties. The foam sheets can be shaped to fit electronic items like computers, TVs, and other electronic devices, providing cushioning and anti-static protection during transport and storage.

- Medical packaging: EPS foam sheets are also used in medical packaging applications due to their ability to provide a sterile environment. The foam sheets are used to line medical packaging containers like test tubes, vials, and syringes to maintain sterile conditions during transport and storage. Overall, EPS foam sheets have a wide range of packaging applications due to their versatility, durability, and insulating properties.

Our E.P.E. Foam Sheet Cut Pieces are manufactured with best technology available, Highly Precise and Highly Accurate Cut Piece. They are used for packing in various industries, Prevent damage to Your product, act as barrier to prevent scratch, unmatched quality are features of our product.

Quality Assurance and Best Prices guaranteed.